A&A ELECTROPLATERS

SHINE AND PROTECT.

YOUR ELECTROPLATING EXPERTS

From Precision Coating to Lasting Quality, We’ve Got You Covered.

OUR SOLUTIONS FOR LASTING DURABILITY

Nickel Electroplating

Nickel plating is widely used for its excellent corrosion resistance and smooth finish. It's often used for industrial and decorative purposes.

-

Corrosion Resistance: Protects against rust and environmental damage.

-

Durable Finish: Provides a hard, smooth surface ideal for wear resistance.

-

Versatile Applications: Common in automotive, aerospace, and electronics.

Copper Electroplating

Copper plating is used for its conductivity and as a base layer for other metals. It’s essential in electronics and electrical applications.

-

Electrical Conductivity: Ideal for electrical components and circuits.

-

Base Layer for Other Platings: Often used as an undercoat for gold or silver plating.

-

Cost-Effective: Provides excellent performance at a relatively low cost.

Chrome Electroplating

Chrome plating provides a hard, shiny finish and is often used to enhance the appearance and durability of automotive and industrial parts

-

High Durability: Resistant to scratches, corrosion, and wear.

-

Enhanced Aesthetics: Popular in automotive and decorative finishes.

-

Improved Hardness: Provides a tough surface for machinery and tools.

Silver Electroplating

Silver plating is often used for its aesthetic appeal and conductivity. It’s applied to a variety of products, from jewelry to electronics.

-

Bright, Shiny Finish: Ideal for decorative and jewelry applications.

-

High Conductivity: Used in electronics and connectors.

-

Antibacterial Properties: Often used in medical and food-related industries.

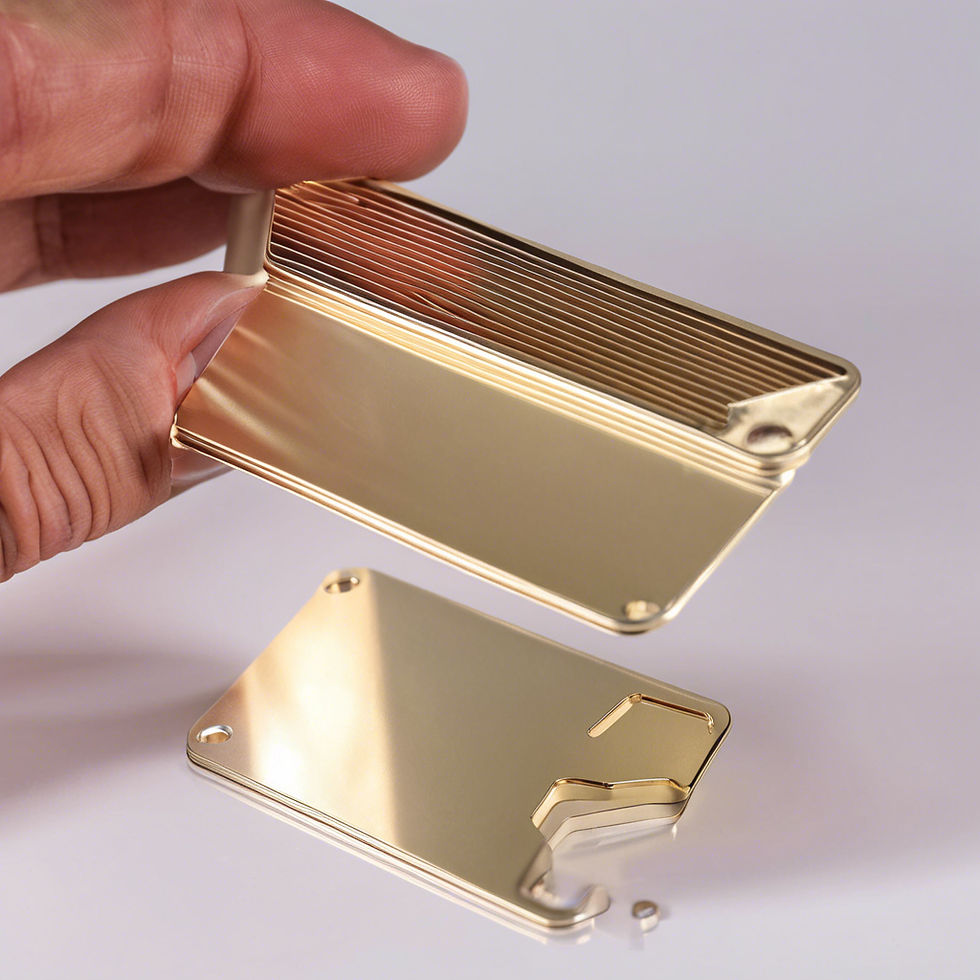

Gold Electroplating

A&A Electroplaters specializes in gold electroplating to enhance functionality and appearance. Known for its superior corrosion resistance and conductivity, gold plating is ideal for high-precision applications in the manufacturing industry.

-

Premium Finish: Offers a luxurious, reflective surface for high-end components.

-

Corrosion Resistance: Extends the lifespan of critical parts by preventing tarnish and wear.

-

High Conductivity: Ensures reliable performance in electrical and electronic manufacturing.

-

Industrial Versatility: Widely used in aerospace, automotive, and electronic industries.

Black Electroplating

A&A Electroplaters provides black electroplating services that deliver a durable, sleek finish, catering to both functional and aesthetic needs in manufacturing.

-

Sleek Appearance: Achieves a unique black finish for high-end industrial components.

-

Enhanced Durability: Protects against wear and tear in demanding environments.

-

Corrosion Protection: Ensures long-term reliability of metal surfaces.

-

Precision Applications: Perfect for tools, automotive parts, and industrial machinery.

Tin Electroplating

A&A Electroplaters offers tin electroplating for manufacturing industries requiring corrosion resistance, solderability, and non-toxic coatings for critical components.

-

Solderable Surface: Ensures dependable electrical connections for electronic manufacturing.

-

Corrosion Protection: Safeguards components from rust and environmental damage.

-

Non-Toxic Coating: Suitable for food-grade equipment and medical devices.

-

Cost-Efficient Solution: Delivers durable performance at an economical price.

ABOUT A&AELECTROPLATING PTY LTD

At A&A Electroplating, we take pride in our highly skilled and dedicated team of professionals who are committed to delivering top-quality electroplating services. Our team culture is built on collaboration, innovation, and a shared passion for excellence. With years of experience across various industries, each team member brings a unique set of skills to the table, ensuring that every project is completed with precision and care.

From our expert technicians to our customer service specialists, every individual at A&A Electroplating plays a vital role in making sure our clients receive exceptional results. We are constantly learning and evolving, keeping up with the latest technologies and best practices in the industry to provide cutting-edge solutions. Together, we create a work environment that fosters creativity, respect, and a commitment to achieving 100% customer satisfaction.

1

MARK MCHALE

Managing Director

2

CECILIA MCHALE

Chief Financial Officer

3

MICHAEL ADU

Operations Manager

4

TRENT MCHALE

Plant Supervisor